New Valve System Ensures Constant Fresh Water at Ipswich Hospital

A Keraflo Twin KP valve system is ensuring constant fresh water from hospital storage tanks at the Garrett Anderson Centre (GAC), a self-contained building within the Ipswich Hospital complex.

The GAC is supplied with water through a break tank on the ground floor that, in turn, feeds a storage tank in the roof through a booster set. Both tanks are divided into two, which provides easy maintenance and cleaning access while ensuring an uninterrupted supply of water to the 24/7 facility.

The problem with having a divided tank is finding two independent valves to refill each side of the tank that both work simultaneously. If one valve opens earlier than the valve on the other side of the tank and keeps up with demand, the other valve won’t open at all. This can lead to problems with the health and hygiene of the water supply on the side with the later opening valve, as the water tends to stagnate.

The problem with having a divided tank is finding two independent valves to refill each side of the tank that both work simultaneously. If one valve opens earlier than the valve on the other side of the tank and keeps up with demand, the other valve won’t open at all. This can lead to problems with the health and hygiene of the water supply on the side with the later opening valve, as the water tends to stagnate.

Furthermore, if one valve tends to open first, it leads to uneven wear, such that the earlier opening valve will gradually become looser, while the valve feeding the other side of the tank can become gradually stiffer and this will only accentuate the differential opening rates. Issues can then occur in the static tank with bacterial growth, stagnant water and of course the ever-present danger of Legionnaire’s Disease. In severe cases a biofilm can occur.

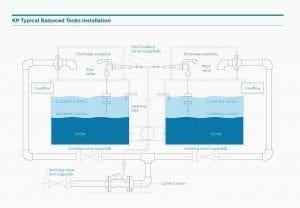

The Keraflo Twin KP is a new system that was developed with Kier Construction to overcome this problem and offers a unique solution to the market. The Twin KP uses two main control valves, one on each side to fill the tank, supported by two smaller pilot valves. The two main control valves are triggered by the pilot valves; whichever pilot valve opens first then opens both control valves simultaneously, thereby filling both sides of the tank.

Neil Weston, sales manager for Keraflo, said: “The Twin KP solution with its double valve system overcomes the issue of any imbalance in refreshing the water stored within either side of the tank.

“Both sides fill at the same rate, ensuring regular replacement and refreshment of the stored water to the GAC.

“What’s more, the design ensures that servicing and maintenance is just as easy for the Twin KP as for a conventional system. Shutting the valves on one side down and isolating that end of the tank still allows the engineer to keep the other side in service.”

For product support or installation advice, contact our dedicated support staff today.